To set up a shaft motor using a TITAN servo controller, connect the shaft motor with the incremental encoder. To learn how to set up a motor without an encoder, please visit our HALL SENSOR TUTORIAL.

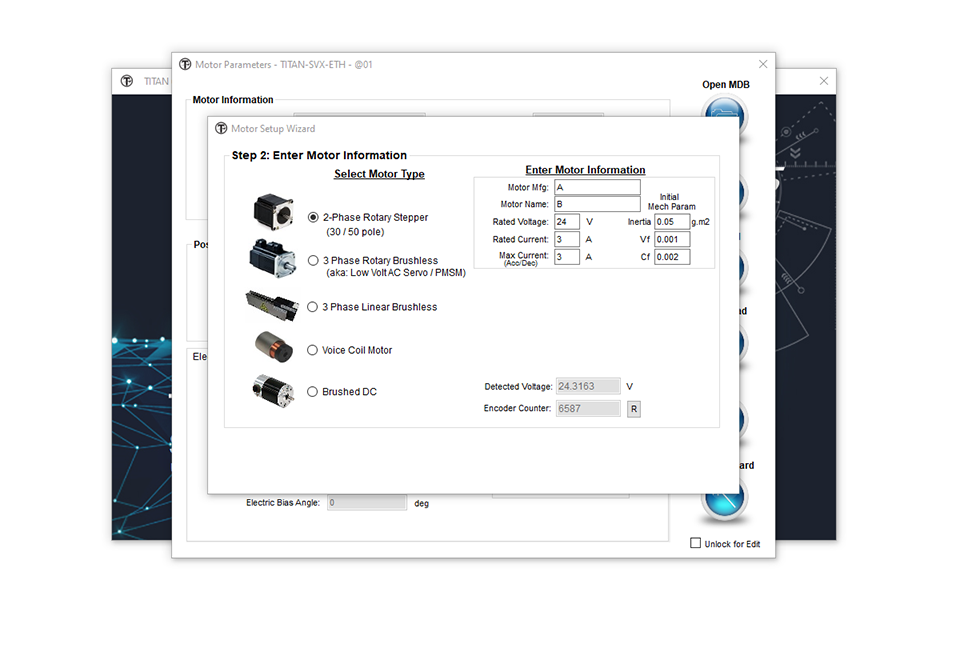

Power up the motor controller and check to confirm the USB communication is working. Go to the motor setup window and open the motor data base wizard. Select the 3-phase linear brushless motor.

Enter the motor manufacturer, motor name, voltage, rated current, and max current for the motor. Then, input the magnet pair distance and encoder resolution for the motor. For the motor used in our tutorial video, the magnet pole-pitch is 30 millimeters and the encoder resolution is 1 micron.

Below the motor information inputs, you can see the encoder count and the power supply voltage. You can manually move the motor and see the encoder count changing.

Next, we can perform the auto detect routine. Make sure the motor doesn't have any load and is on a stable surface. Move the motor stage to the middle to let the TITAN check for encoder direction.

Input the soft limit values. For the negative value, set the position to 0 when it is near the negative end of the shaft and send the positive limit to the position near the positive end of the shaft. The electrical and mechanical parameters will be automatically determined.

Once the testing is done, save the parameters to the database file so we can reuse the database when using the same motor with other TITAN motor controllers.

To test the motion of the shaft motor, enable the motor and confirm that it is in position. Within the "Test Drive" window, you can try different jogging or position moves to test the motion of the motor. Note that the soft limits are enabled from the previous detection routine.

Make sure that the position and current error detection is enabled to avoid damaging the system. This is especially important for linear motors.

Once you attach a load to the motor, you will want to tune the system parameters from the "Tuning" window.

Go to the "Configuration" window to see the configuration settings. The "Parameter" window will show you the full summary of the setup, which includes the motor database values and the full system configuration values.

Once everything is finalized, a store to flash can be performed to save all settings to the motor controller. You can also save the system settings to a file so that they can be loaded to another TITAN controller with the same setup.